This type of bearing may be considered the most important one from the commercial point of view, since the pot bearings represent the largest portion of the bearings market in the world.

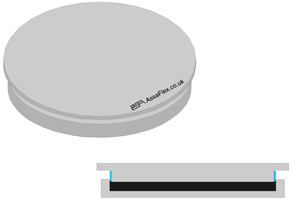

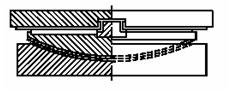

Pot bearings consist of an elastomeric pad confined in a steel cylindrical pot by means of a close fitting piston and an internal seal. They can be combined with a sliding element in to accommodate translational movements in one or any direction.

The most important detail of the pot bearings is the seal, preventing the leakage of the Elastomer / rubber through the gap between pot and piston and governing the durability under repeated rotations.

Spherical and Cylindrical PTFE Bearings

Cylindrical bearings consist of a backing plate with a convex cylindrical surface (rotational element) and a backing plate with a concave cylindrical surface between which a PTFE sheet and the mating material form a curved sliding surface. Cylindrical PTFE bearings are also used in combination with flat sliding elements and guides to form free or guided bearings.

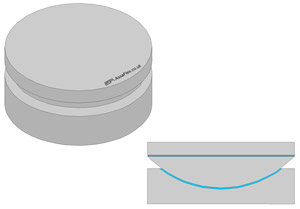

Spherical PTFE bearing consist of a backing plate with a convex spherical surface (rotational element) and a backing plate with a concave spherical surface between which a PTFE sheet and the mating material form a curved sliding surface.

Types of PTFE spherical bearings

a) Fixed By sliding surface

Fixed spherical bearings may transfer the horizontal forces through the curved surface and in that

case consist of two plates with one interposed sliding surface (see Fig a).

Fig a

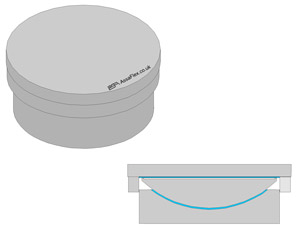

b) Fixed By restraining Ring

In alternative way they may transfer the horizontal forces through a restraining ring and in that case they consist of three plates with two sliding surfaces, one curved and one flat (see Fig. b).

Fig. b

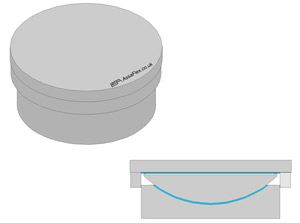

c) Free sliding in any direction

Spherical PTFE bearings are also used in combination with flat sliding elements to form free sliding bearings (See Fig. c).

Fig. c

d) Guided by Internal Guide

In combination with flat sliding element and guides to form sliding guided bearings. The guide may be internal and in that case the horizontal forces are transferred through the spherical surface In that case the horizontal forces are subject to limitations given by the stress distribution on the PTFE surface, (see Fig d).

Fig d

e) Guided by External Guide

In alternative, for greater level of horizontal forces, the use of two external guides is preferred (See Fig. e).

Fig. e

Pot Bearing Specifications

Quality Control:

Bearings are important elements of structures, such as bridges and viaducts, ensuring that they operate correctly. The durability of the structure depends on their quality, as they are in a constant state of use.

The life expectancy of bearings is the result both of their intrinsic qualities and of the care taken over.

The quality of these products depends on expertise in the manufacturing process. Quality Assurance provisions should enable you the client to:

- Convey the quality required in terms of manufacturing methods

- Obtain the quality required

- Check that it has achieved the quality required

- Justify subsequently that it has been reached and checked.

- AssaFlex products are checked independently at certain intervals such as Esfahan’s Polytechnics or other reputable laboratories.

CE Marking

Quality control procedures will be implemented in the factory such as:

- Tests on samples taken in the factory in accordance with a prescribed test programme.

- Inspection of the ecstatic of the products

CE marking will be then placed on the products.

The last stage before leaving the factory is vacuum packed on palletized items.